The way into the heart of our museum

Our Collection

You can find interesting stories on this page, not only about objects in our collection but also the history of Newtown and its significance to the handloom weaving industry. You can also find jigsaws created from our objects that you can do online, and the details of our past exhibitions. With advance notice, we can arrange to show you some of the objects that are safely tucked away in our store room.

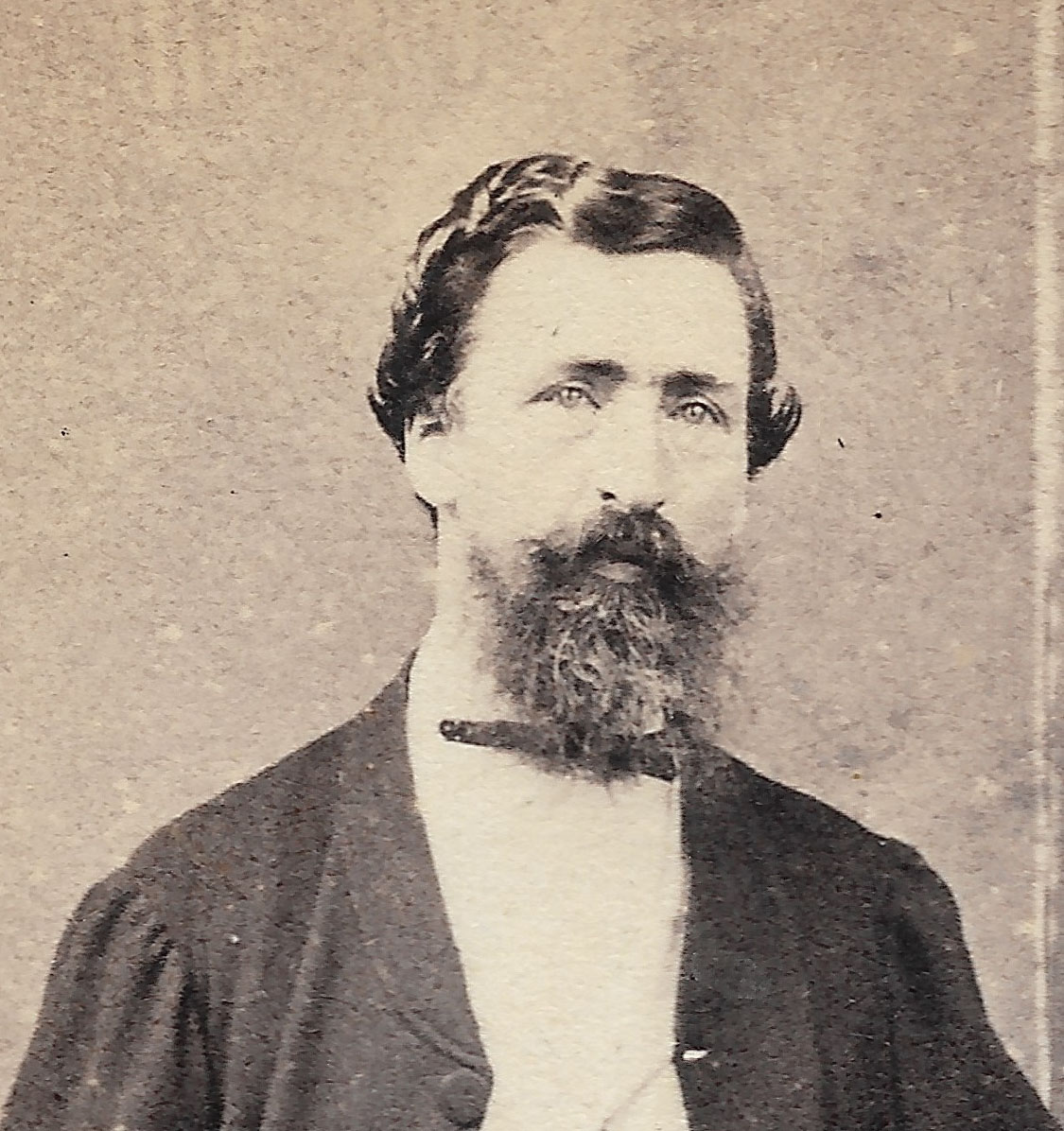

William Pugh Newtown's Unsung Visionary

He was a significant figure in re-shaping Newtown in the early days of the flannel industry

READ MORE

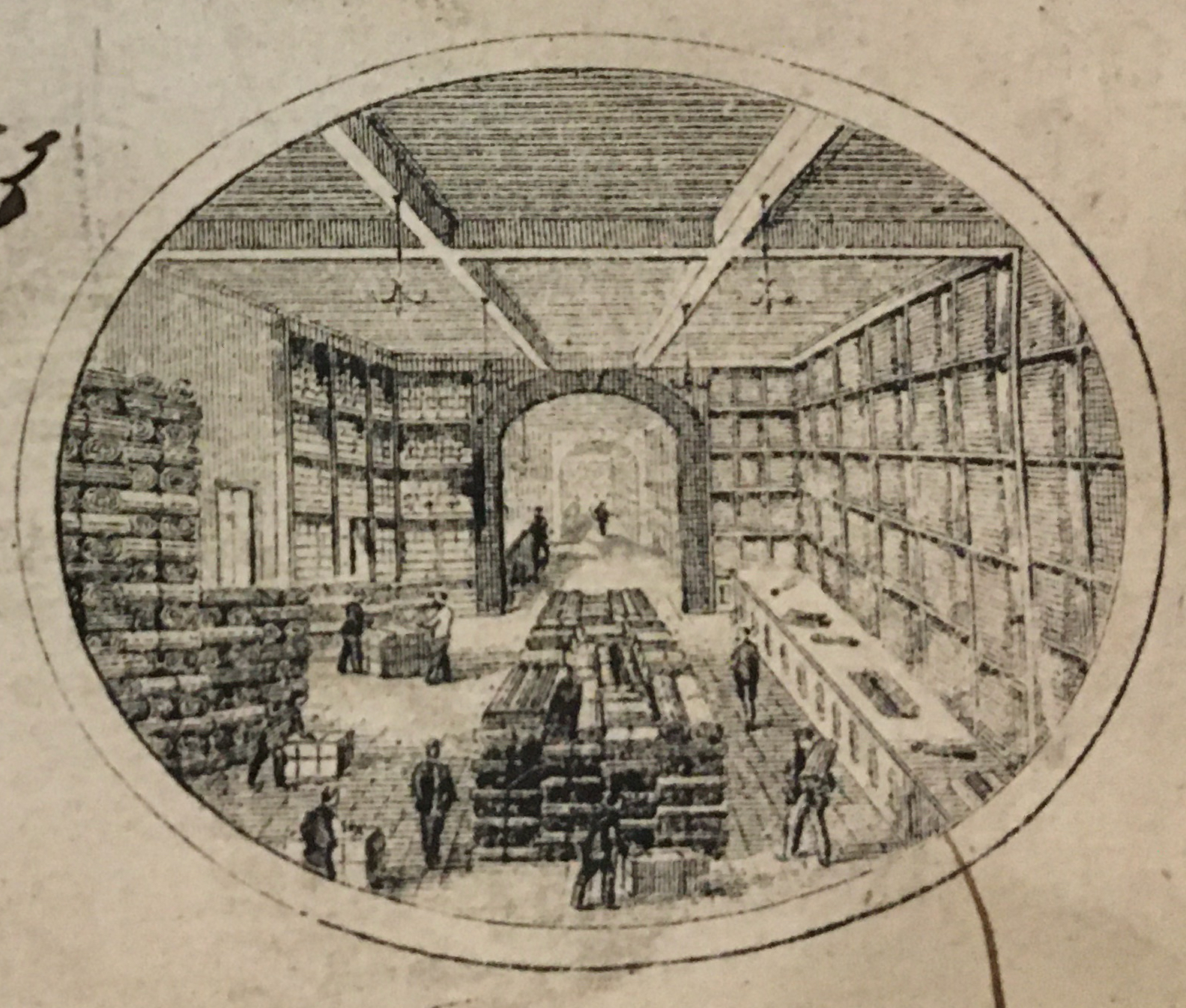

The first Royal Welsh Warehouse

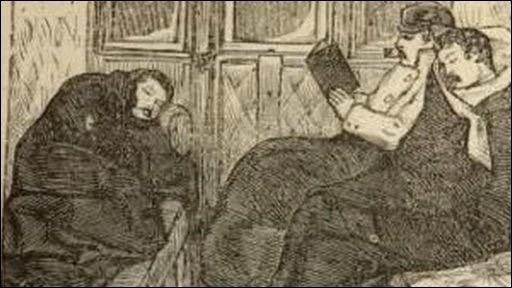

This small engraving shows the interior of Pryce Jones's first Royal Welsh Warehouse.

READ MORE

Royal Warrants and the art of self-promotion

Pryce Jones and the story of his Royal patronage

READ MORE

Hats and caps

We have a traditional Welsh hat as well as some typical late 1800s caps in our collection. Check out their story.

READ MORE

Shopping in the Victorian era

When researching the 2023 exhibition about Amelia Ray , we looked in our collection for related objects. This crochet purse would have been used to carry coins in the late 1800s. Check out the story.

READ MORE

Newtown emigrants in mid 1800s

Humphrey Lewis and Edward Humphreys

Written accounts of the voyages of these men leaving Newtown for a new life overseas

READ MORE

Welsh flannel - more of the story.

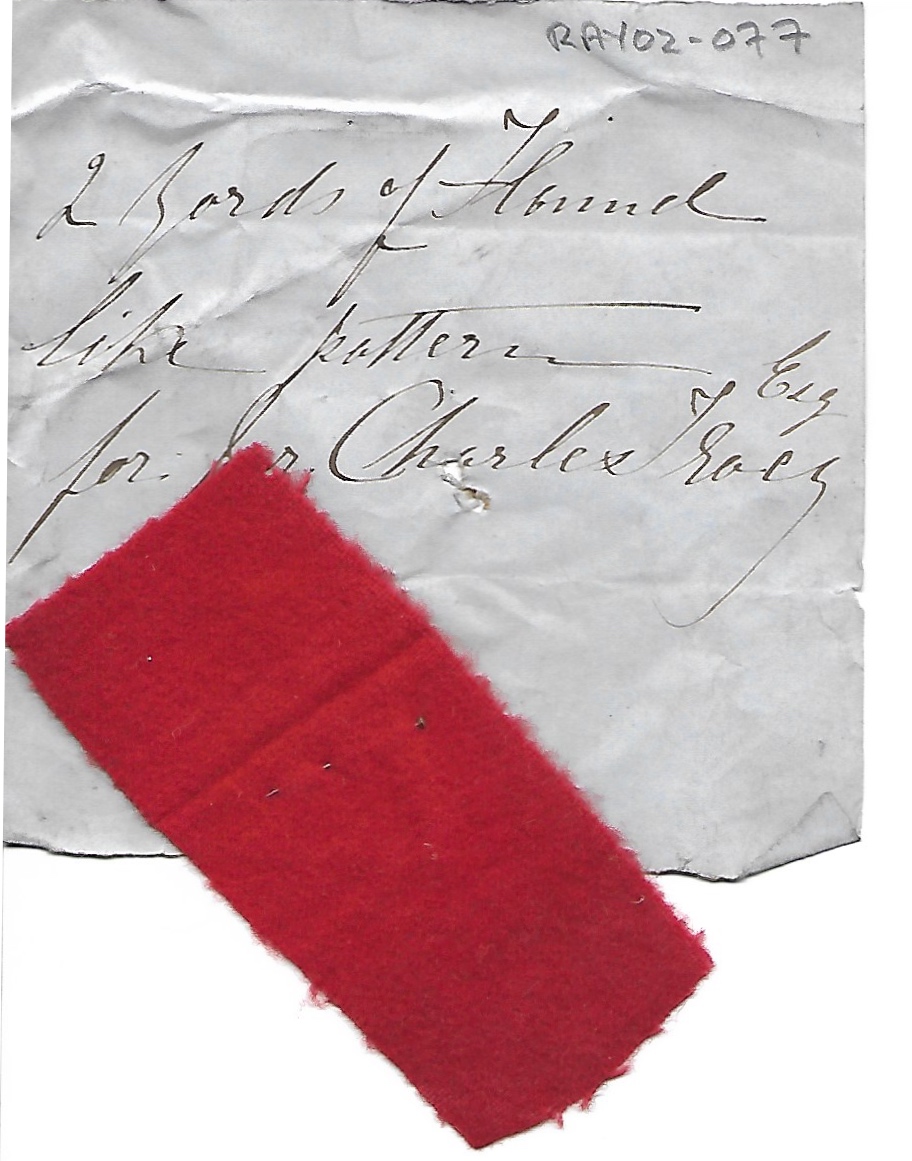

This note, with a small sample of red flannel pinned to it, is just one of nearly 1500 documents in our Amelia Ray collection. She was the owner of a draper's shop in High Street, Newtown in the 1870s and she is the subject of our 2023 Summer Exhibition.

The sample of red flannel is important as everyday fabrics from that period are uncommon, but they form an important part of the story of our Museum as fine quality flannel was highly sought after. Read the story attached for more detail and make sure you visit us to see our fascinating exhibition - Amelia Ray: A Victorian Entrepreneur At The Cutting Edge which opens on 2 May 2023.

READ MORE

Detail from Knocker-up stick - it has a more exciting story to tell.

Always a bit of a mystery, some new information about the stick came to light during an Antiques Road Show episode.

READ MORE

A little white jug with a big history

This small jug was donated to the Museum in 2007. Although not in good condition, it commemorates a major train disaster at Abermule, near Newtown on 26 January 1921, so it has a big story to tell.

READ MORE

The cape and jacket of the wedding dress of Ann Williams

This three-piece dress belonging to Ann Rogers doesn’t exactly scream ‘wedding dress’ to a modern eye. Emily Connell, explains why this was the style of choice for someone of Ann’s social standing.

READ MORE

A Victorian Wedding

On 29th April 1881, farmer Thomas Rogers married Ann Williams, also of farming stock and eight years his junior, in the ancient church of St Bueno in Bettws Cedewain.

READ MORE

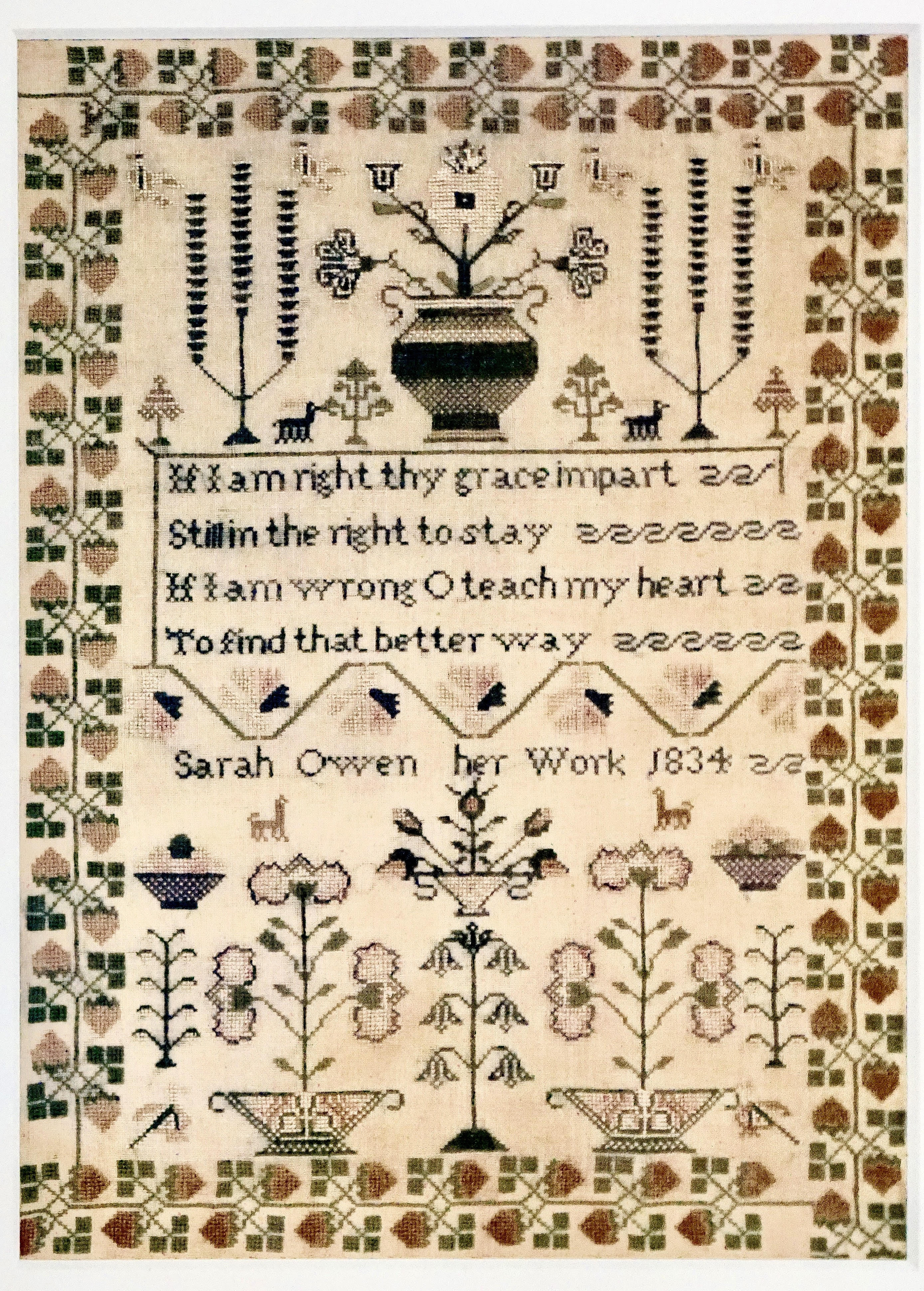

Sarah Owen sampler

Sarah Owen born in 1798, was the niece of Robert Owen, famous socialist pioneer. Her father Richard was one of Robert’s brothers. In 1841 she lived in Newtown with her mother, also called Sarah, and sister Charlotte, in Glandwr House, Pool Road and was variously described as a Landed Proprietor, and an Annuitant in the various later census records. At a time when it was common for wealthier families to have resident servants, there is no such record in Sarah Owen’s household.

READ MORE

Mary Jones, Pedlar doll

One of the items on display in the Newtown Textile Museum is this lovely model doll of a pedlar. The details of her stock are amazing.

Mary Jones was born in 1823 in Llanllwchaiarn and her mother Anne Jones born in 1790 in Denbighshire. In 1871 they are recorded, as living in Frankwell, Llanllwchaiarn and her occupation was Hawker.

READ MORE

Loving cup

A loving cup is a large ornamental drinking vessel. It is commonly used as a presentation trophy to winners of games, or as a shared drinking container at ceremonial events such as weddings or banquets. Loving cups usually feature two handles, and are frequently made of silver.

READ MORE

Clog making

The Museum has a large collection of clog-making equipment and the associated leather for the production of new ones.

READ MORE

Christmas cards

The Textile Museum has a few examples of old Christmas cards in its collection, of which this is one. The idea of sending Christmas cards began in 1843 when Sir Henry Cole (founder of the Victoria & Albert Museum and a keen supporter of the Penny Post) asked an artist friend J C Horsley to design a card for Cole to send to his friends instead of writing a letter. It took several decades for the idea to become popular

READ MORE

1903 Cycling Club

No lycra is visible, but there are plenty of middle-aged men in this 1903 photograph of members of Newtown Cycling Club. To be fair, the age range is quite broad with young boys as well as some very mature looking men, but no women!

READ MORE

Newtown Old Church

The relief carving of the Old Church in Newtown, once the parish church of the town known as St Mary’s, is one of four similar oak carvings made by John Jones, of Parkers Lane, Newtown.

READ MORE

Wedding shoes

Museums cherish objects of all sorts, but best of all they like to have ‘provenance’ and the ability to date the things in their care. Nowadays at the Newtown Textile Museum we only collect objects from the Newtown area, but in 1967 when the Museum was established, it was more important to collect treasures that were being offered, as long as the history was known and they were for the correct period.

READ MORE

A prize worth having - presented for 100yd flat running race

J E Morris, brother to an international footballer Dicky Morris made a name for himself in the summer of 1907. This much is known from the newspaper account.

READ MORE

Dr. Richard Jones and his wife Jane

These two portraits were donated to the Newtown Textile Museum by JKD Lloyd, author and antiquary of Montgomery. He was closely involved with the establishment of the Museum in Newtown in the 1960s.

READ MORE

Newtown to Llanidloes Railway

A surge in railway building in England in the mid-1840s did not extend into midWales. The canal was available as far as Newtown but beyond that, transport was difficult, the first mail coach to reach Caersws ran in 1852. Various proposals at the time for railway lines through to the coast at Aberystwyth, and a line to link Manchester to Milford Haven, were considered, but did not progress.

READ MORE

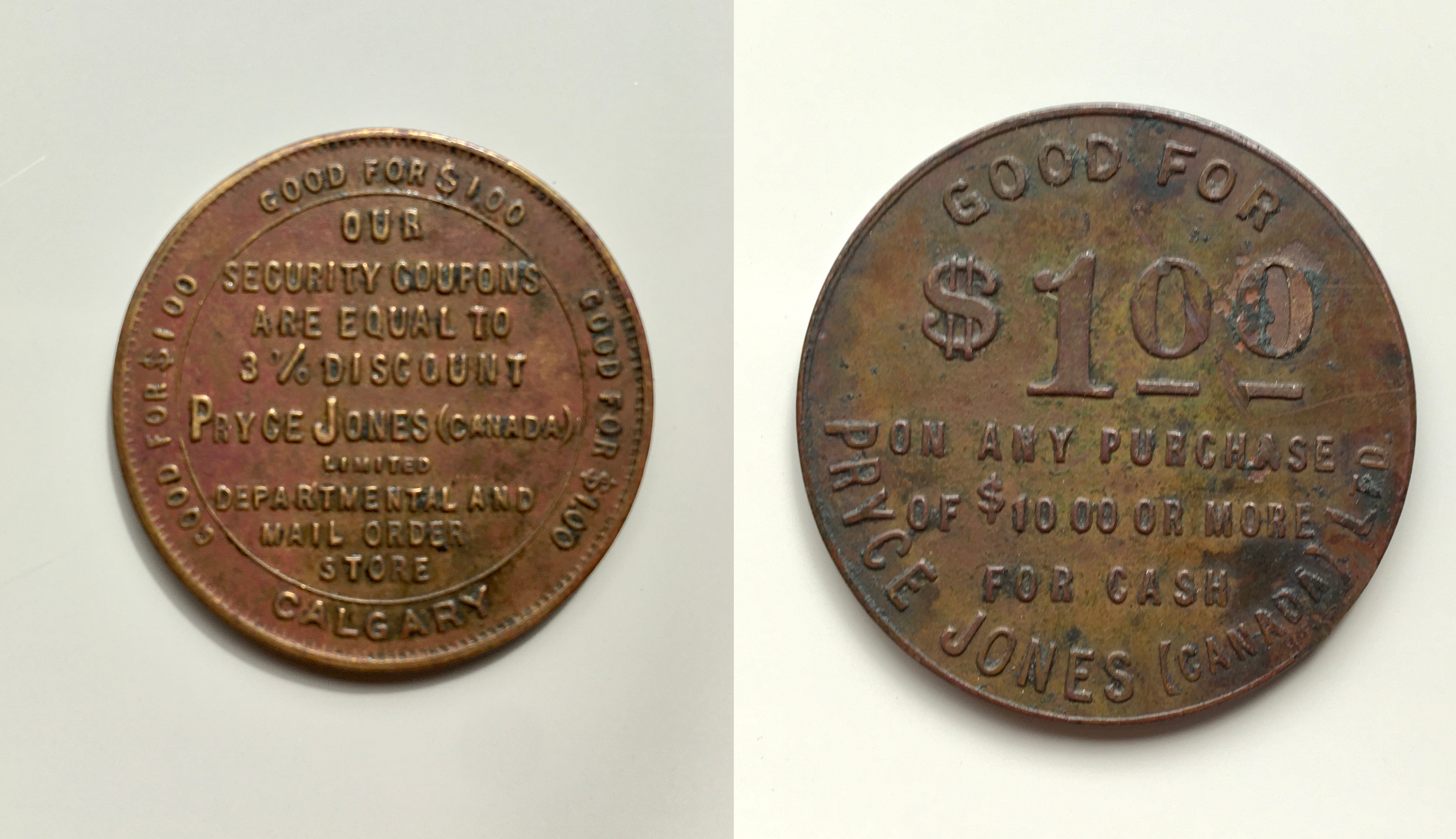

Shopper tokens - an early Canadian example.

Some of us remember Green Shield Stamps, first developed in 1896 and running until the 1960s, and many of us now own a loyalty shopping card, or perhaps several. Around 1900 seems to have been the time when labels, tickets and stamps became popular, at least in America, as a means of giving customers a small reward for their purchases. The trend has continued to this day.

READ MORE

Spinning – a great wheel

Spinning is the process of drawing out and twisting fibres into a continuous thread. It has been done for centuries.

READ MORE

What is Flannel, and how is it different to Worsted

We are often asked about the definition of flannel, and how it differs from another woollen fabric known as worsted. The simple answer lies in the type of woollen thread used in the production of the cloth.

READ MORE

Newtown White Stars

This photograph of 1879 shows the victorious Newtown White Stars football team. It is special in several ways.

READ MORE

Euklisia Rug

The Euklisia rug, thought to be the world’s first commercially produced sleeping bag, was patented by Newtown entrepreneur Pryce Jones in 1876. It is more of a folded rug than a bag, but it featured a sewn-in blow-up pillow lined with rubber, and was thick and warm, with fasteners to hold it together.

READ MORE

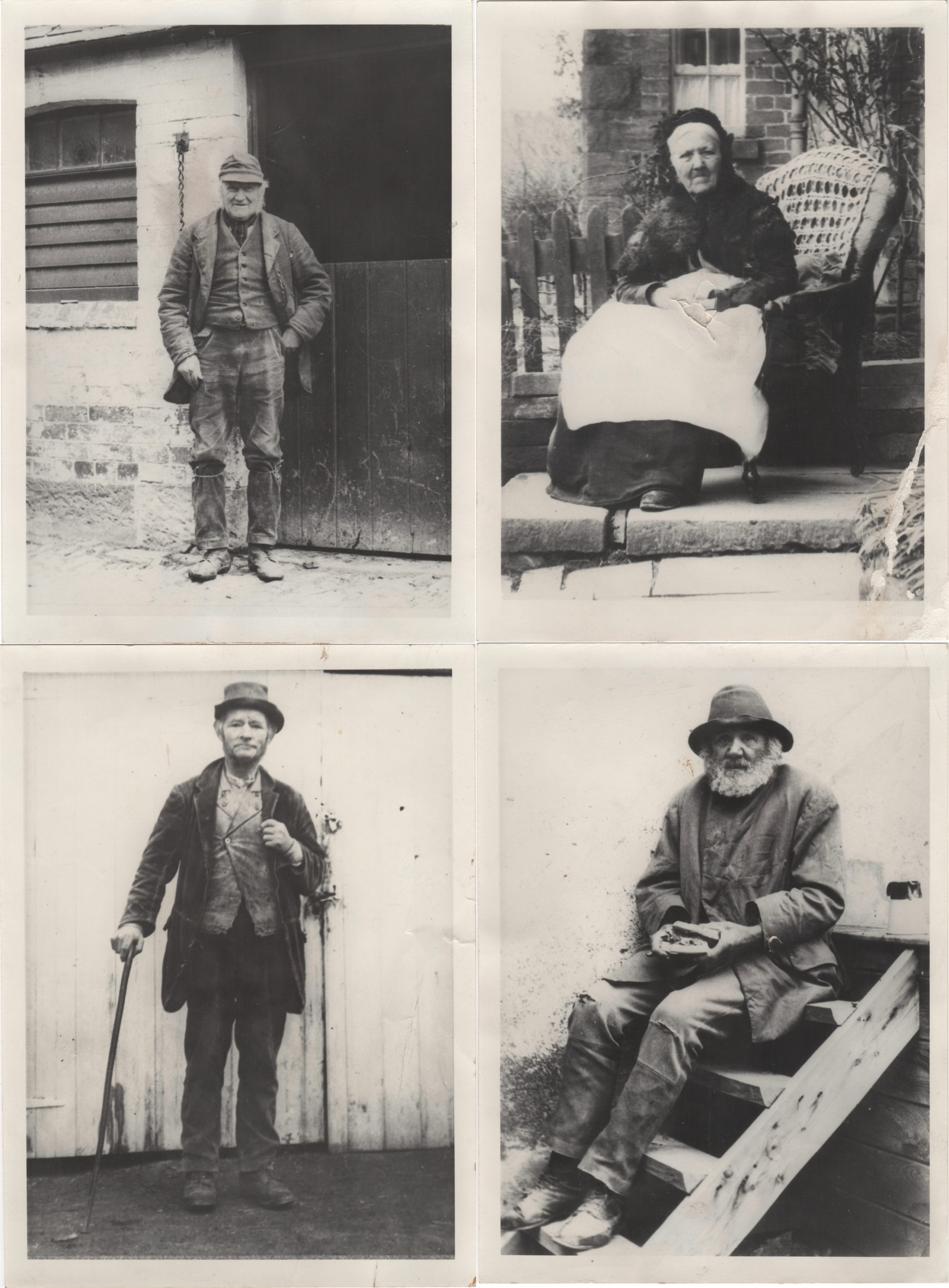

Kerry Characters

The four photographs on the Come-Inside page are from a series of 25 images of people living in Kerry in the early 20th century taken by J W Poundley (1873-1932).

READ MORE

Pryce Jones Vienna Exhibition meda

Pryce Jones, a native of Newtown, began life as a humble draper’s apprentice but became a pioneer of the mail order business and revived the flagging mid Wales textile industry in the second half of the nineteenth century.

READ MORE

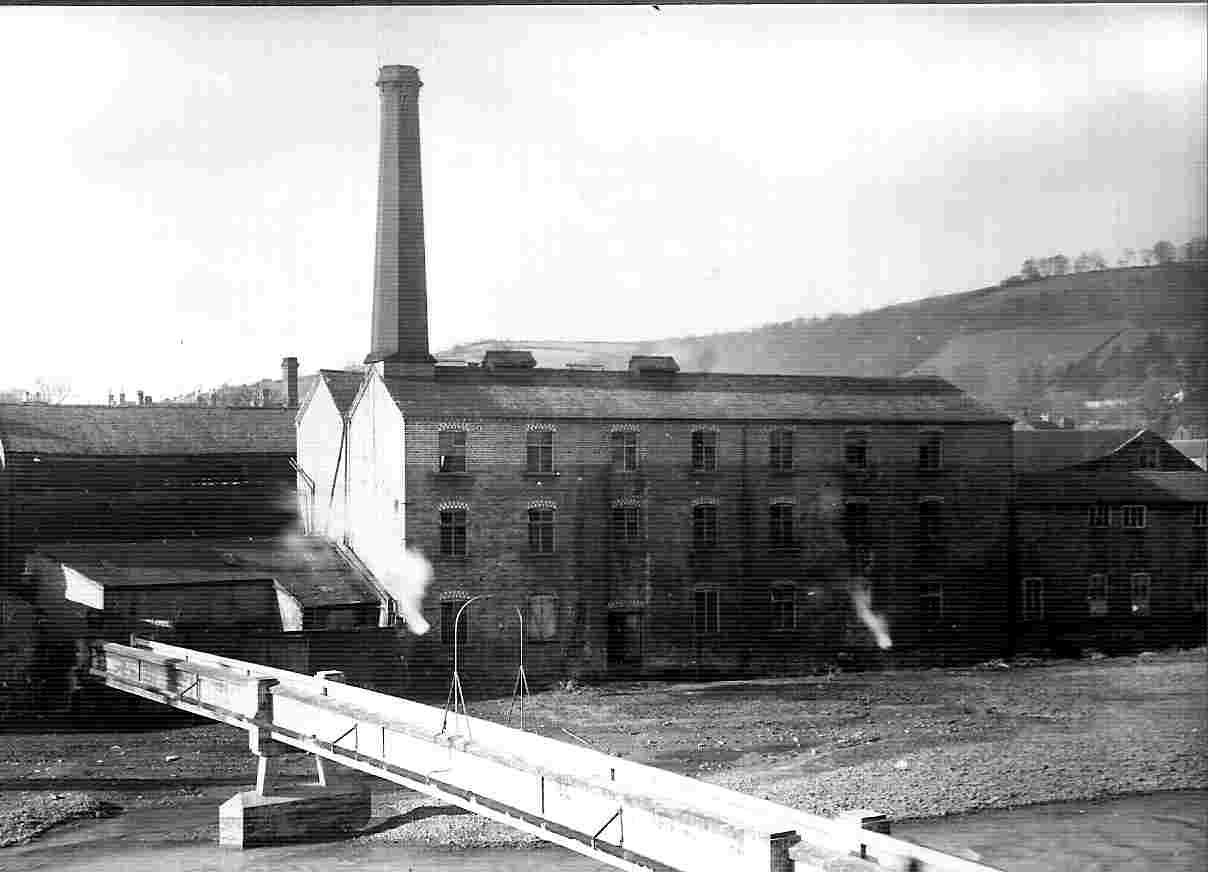

Lewis and Son (Newtown) Ltd:

Four generations of a family tanning business 1829 saw the start of the Lewis family tannery when Lewis Lewis (1791–1861) moved into No5 Severn Square and took over the existing business behind with its tan pits, bark sheds and leather drying rooms with louvre-boarded sides.

READ MORE

Tally check token George Morgan, Crescent Street Mills, Newtown, c188

During the early years of the nineteenth century, Newtown developed as a centre of the flannel industry.